Construction Lagging

Quality Lagging Lumber

We offer a large inventory of lagging material, which provides the necessary boards and beams to support underground trenches, stabilize excavation sites, and prevent soil damage on construction sites. Here are typical use cases for lagging lumber.

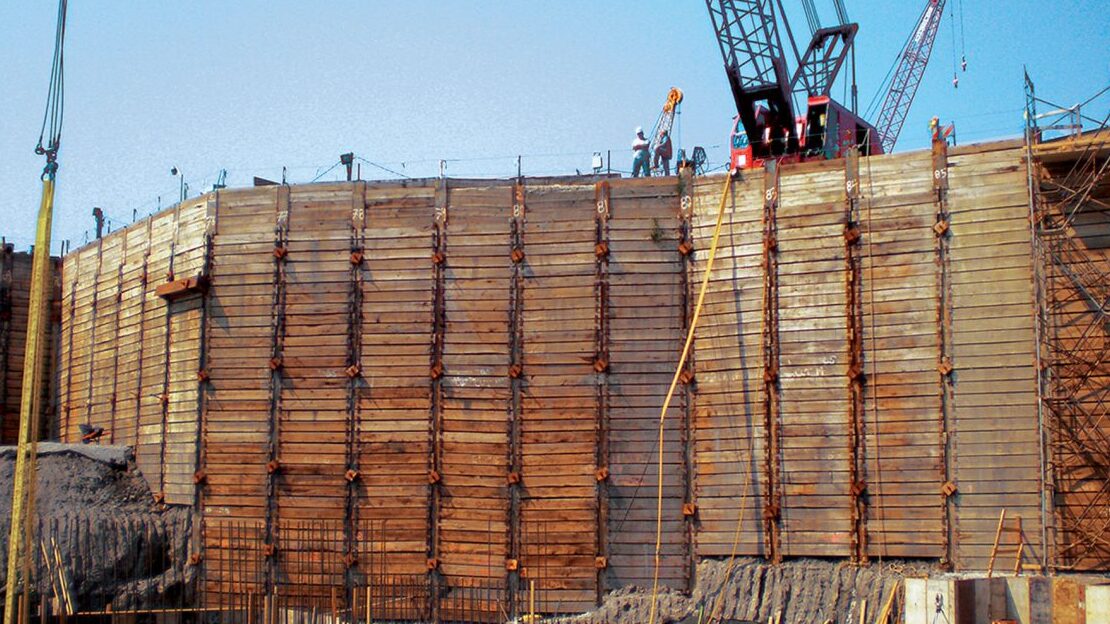

Soldier Pile Lagging

Lagging is placed between the soldier piles and is commonly used systems for supporting excavations in urban environments where property lines, roads, and utilities prohibit sloped or benched excavations. Soldier pile and walls are more economical and faster to construct than many other earth shoring systems.

Lagging Lumber Retaining Walls

Beam and lagging anchored retaining walls are commonly used to support open excavations and restrict lateral movements. Lion lagging lumber and lumber products provide increased safety to nearby structures and utilities against excessive deformations and loss of bearing capacity.

Shoring Lumber

Shoring lumber and beams are used to stabilize a structure or excavations. When deep excavations are required, adjacent buildings, streets, and equipment must be protected with strong hardwood shoring timbers. Retaining walls reinforced with shoring can also be secured with cable and anchors.

Hardwood Tunnel Lagging

Lagging for deep foundation, earth retention, and tunneling job sites around the country. If you need a non-standard length, angle or bevel, we can cut to length at any of our sawmills or manufacturing facilities before delivering it to your jobsite.

Product Types

Below are the Lion Lumber products designed for construction lagging.

Blocking, Cribbing, Dunnage and Bracing

Blocking or cribbing is used to level, support, or stack items for transport or construction. Blocking and bracing is a load securement method using lumber and metal bars to reduce or inhibit front to rear shifting of freight/cargo.

SPECS

Blocking Lumber & Dunnage

- Thicknesses from 3/4″ to 16″

- Widths from 2″ to 16″

- Lengths up to 30 feet

- Made to order

- Export Requirements*

The dunnage mark on lumber identifies wood as being heat-treated and debarked and in compliance with ISPM-15 standards for export shipments. Dunnage-stamped lumber is typically used for blocking, bracing, and chocking inside shipping containers and used primarily by wood packaging manufacturers, shippers, and freight consolidators. At a minimum, the dunnage mark must be applied legibly every 24 inches.

Precision Cut to Length

- Special cut hardwood blocking, cross-outs, and dunnage lumber used for shipping and packing material

Lagging Lumber

Delivered, Cut-to-Length Lagging Lumber

SPECS

Specify lengths and species of lagging lumber sizes required:

- Choice of mixed hardwood, southern yellow pine, or Douglas fir

- 3″ x 8″ (8′, 10′ and 12′ lengths)

- 3″ x 10″ (8′, 10′ and 12′ lengths)

- 3″ x 12″ (8′, 10′ and 12′ lengths)

- 4″ x 8″ (8′, 10′ and 12′ lengths)

- 4″ x 10″ (8′, 10′ and 12′ lengths)

- 4″ x 12″ (8′, 10′ and 12′ lengths)

- Custom lengths up to 40′

Pre-Made Lagging Panels

SPECS

- Provide us with a list of walls and lengths, and we will pre-build the panels for fast and easy installation.

- Mixed dense hardwood, southern yellow pine lagging, or Douglas fir

- 24- to 48-hour delivery available

Pre-made lagging panels are made to specifications and delivered to your jobsite so there is no cutting required. Installation is as fast as the panels can be dropped in the soldier pilings.

Soldier beams and timber lagging panels in many cases will be the most economical choice for support of excavation. Excavations are supported using steel soldier beams with timber lagging boards, or pre-cut lagging panels installed between them as the excavation progresses.

Shaft & Tunnel Lagging

Lagging for deep foundation, mine shaft earth retention, and tunneling job sites around the country. End cuts of the lagging can be beveled to fit round wall requirements.

Hardwood lagging is primarily used for shoring and framing construction projects including pipeline, sewer, foundation, bridge, mining tunnels and shafts, and other underground applications.

SPECS

- Cut to length

- Beveled shielding end cuts available

- Hardwood and southern yellow pine (SYP)

- Untreated

Hardwood Timbers

Lion Lumber can also provide industrial-grade hardwood timbers of various sizes and lengths up to 40′. These hardwood timbers can be used in retaining walls, shoring, and other subterranean uses.

If you need a non-standard length, we can cut it to length at any of our sawmills or manufacturing facility before delivering it to your job site.